For various reasons the seat has been slow to develop. However, I’m enthusiastic to get this finished so it can be ticked off the list of things to do. Being the kinda guy who is always happy to learn new things, I I’m going to have a go myself. Because I’m new to the upholstery gig I presume this will not be my only effort so I’ll start with a material that I have been enthusiastic to work with; cork leather.

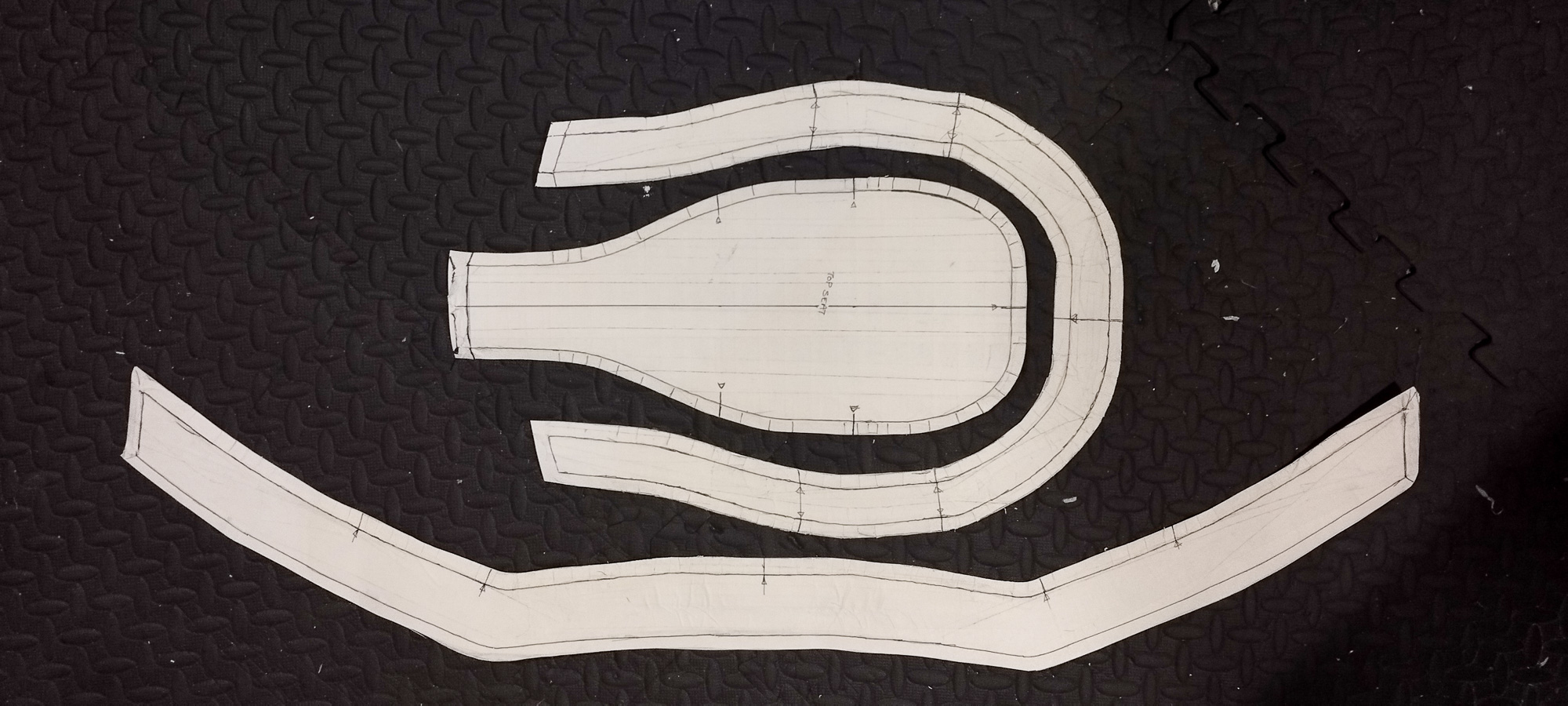

Initially I made the pattern by laying masking tape on the 3D print then cutting it out. Have now transferred the pattern to proper pattern paper in a workshop.

Used two types of foam based on advice, recycled chip foam for the base to help form a hard edge and take my weight, and a softer one on top to provide some comfort. Cutting and adhering the foam was a pain in the arse. But some work with a cheese grater used under advise of a foam supplier, and a very sharp knife helped to shape it.

Following more advice from fashion technicians who specialist in pattern making I cut and stitched a toile (pronounced ‘twaal’) to mock up the pattern and ensure it fits. First one suggests that I need to work on the foam a bit more to add volume, but getting there.